Thermography Services

Keep Your Systems Running Smoothly with Non-Invasive and Cost-Effective Thermography Solutions

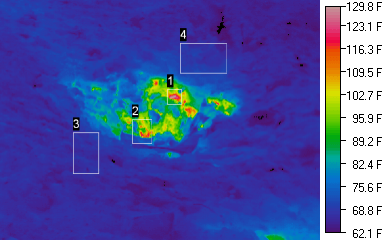

Infrared thermographic testing, or thermography, offers a non-invasive and cost-effective approach to maintenance by measuring and depicting surface temperatures without causing any damage. It's an efficient and economical method that helps detect potential issues before they escalate into costly problems. Furthermore, thermography can be utilized on any energized electrical component, making it a versatile tool for proactive maintenance programs.

CAMCO's Thermography Expertise:

At CAMCO, we have three level-two certified infrared thermographic technicians on staff, expertly trained to operate state-of-the-art infrared technology. With our advanced equipment and expertise, we provide accurate and reliable thermographic testing services and analysis via data interpretation to help you keep your systems running smoothly.

Our Thermography Services Include:

-

Non-Destructive Testing:List Item 1

Thermography allows for the inspection of equipment without the need for physical contact or disruption to operations, ensuring minimal downtime and avoiding unnecessary damage.

-

Effective Fault Detection:List Item 2

By detecting variations in surface temperatures, thermography helps identify potential faults, such as loose connections or overloaded circuits, before they lead to equipment failures or safety hazards.

-

Convenient and Economical:List Item 3

Thermographic testing can be conducted quickly and easily, providing immediate results that enable prompt corrective action to be taken, reducing the risk of downtime and costly repairs.

-

Thermography Windows for Existing Equipment:

Enhance the ease and safety of thermographic inspections by adding thermography windows to your existing equipment. These windows allow for quick and safe access to view critical components without having to open panel doors, reducing the risk of arc flash incidents.

Don't wait for problems to arise. Trust CAMCO Thermography Services to keep your systems operating at their best.

Contact us today to learn more about our services and schedule your thermographic inspection.

Featured Projects

Royal Carribbean

Breaker Maintenance